Innovation in Every Element

In the world of advanced materials, Testbourne stands as a beacon of excellence, offering an extensive and meticulously crafted array of elements. With a commitment to quality, precision and innovation, Testbourne’s range spans across various industries, catering to diverse applications and driving technological advancements. In this blog, we will explore the breadth and depth of Testbourne’s material catalogue.

Sputtering Targets

Sputtering targets are at the heart of thin film deposition technologies. Testbourne’s collection features an assortment of high-purity targets crafted from elements like tantalum and titanium. These sputtering targets ensure precision in coating applications for semiconductors, optics and electronics, enabling the production of high-performance thin films.

Evaporation Materials

Testbourne’s evaporation materials encompass a spectrum of metals and compounds, including tantalum, niobium and aluminium. These materials find their niche in vacuum deposition processes, enabling the creation of thin films for superconductors, optics and specialised coatings, ensuring exceptional quality and performance.

Powders

From tungsten to chromium, Testbourne’s powder range embodies durability and versatility. These powders serve diverse industries, from aerospace to electronics, facilitating the creation of robust materials for cutting-edge applications, including thermal coatings and advanced manufacturing processes.

Single Crystals

Testbourne’s collection of single crystals boasts elements such as silicon and gallium. These crystals exhibit unique properties critical for various electronic and photonic applications, playing a pivotal role in the development of cutting-edge devices like solar cells, LEDs and high-speed transistors.

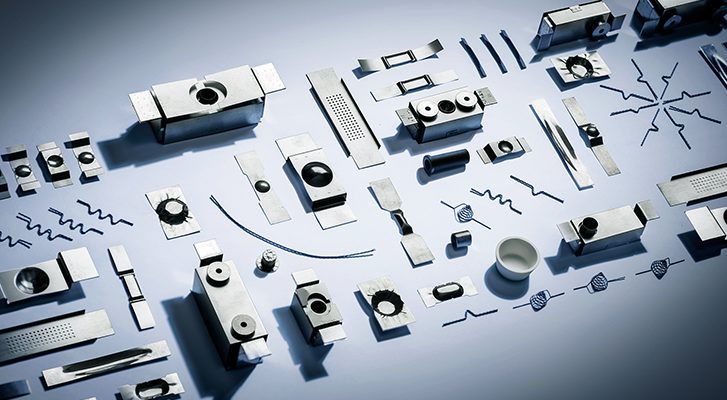

Electron Beam Gun Crucibles

Crucibles for electron beam evaporation are a vital component in thin film deposition systems. Testbourne offers crucibles made from materials like molybdenum, tantalum and tungsten, ensuring reliability and durability in vacuum deposition processes across diverse industries.

High Purity Metal Sheets, Foils, Wires and Rods

Testbourne’s selection of high-purity metals, including copper, aluminium and titanium, provides the foundation for numerous industries. These materials, in various forms, cater to applications demanding exceptional conductivity, corrosion resistance and mechanical properties. Read more in our blog post about high purity materials.

Testbourne’s Diverse Range of Materials

At Testbourne, the emphasis on quality, purity and precision is evident in every element offered. Rigorous quality control measures ensure that each material meets stringent standards, ensuring reliability and consistency in performance across industries. Moreover, Testbourne’s commitment to customisation allows for tailored solutions that meet specific requirements.

The continuous exploration of materials and the dedication to staying at the forefront of technological advancements solidify Testbourne’s position as a trusted partner for industries. As technology evolves, Testbourne remains poised to deliver cutting-edge materials that power innovation and drive progress across global industries. If you require any additional information on any of our materials, please get in touch with our friendly team today.